Diamond-Like Carbon Coating Systems

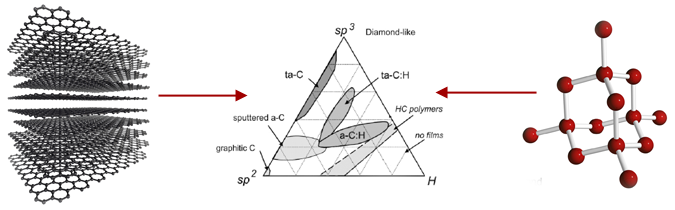

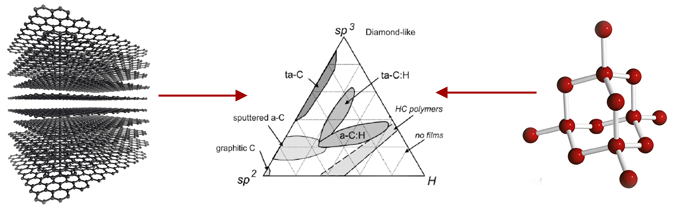

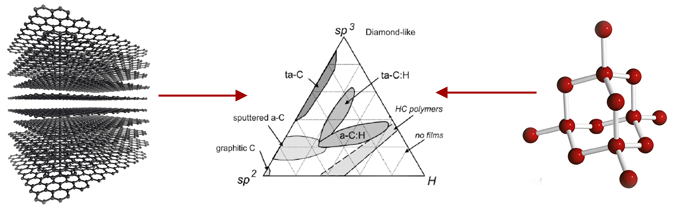

Amorphous Diamond-like-Carbon coatings, typically deposited at substrate temperature <250°C, possess a unique combination of physical, mechanical, chemical and optical properties. The percentage of bonded sp2 & sp3 carbon atoms, metal content and hydrogen content of the films can be manipulated by both the deposition chemistry & methodology (sputter, evaporation, PACVD etc) and the processing parameters applied. Hence, Mustang Vacuum Systems offers a series of deposition chambers and chamber sizes to deposit a range of low friction, highly wear resistant diamond-like-carbon (DLC) and dry lubricant coatings.

Such coatings are often used in demanding automotive, non-ferrous material machining and industrial engineering environments where component surfaces are subjected to high contact pressure, intermittent lubrication or dry sliding and rolling environments which typically leads to the onset of severe abrasive and adhesive wear mechanisms.

DLC coatings are also commonly applied onto various medical and dental instruments and implants to provide a dark black, anti-reflective and bio-compatible surface with enhanced tribological protection properties.

Mustang’s DLC system portfolio can also be routinely used for a wide range of decorative, optical, electrical, defense, sporting and chemical protection applications.

Systems for metal containing (typically Ti or W containing) and a range of metal-free DLC variants plus bond layers are available which also have the ability to control the sp2:sp3 (the graphite : diamond phase composition) of the film, the micro-hardness, friction coefficient, microstructure and can be additionally doped for selected electrical, mechanical and thermal applications. |