|

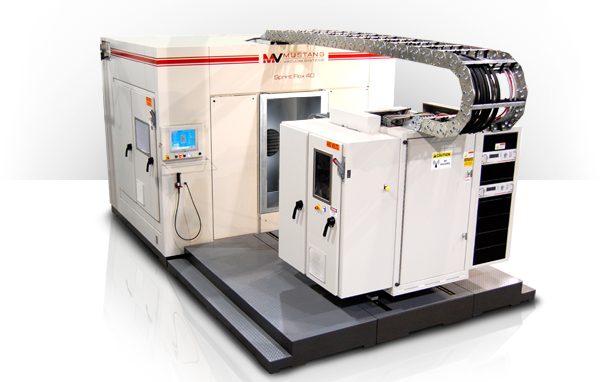

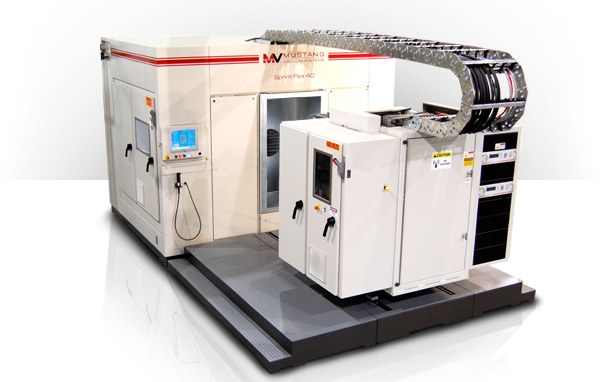

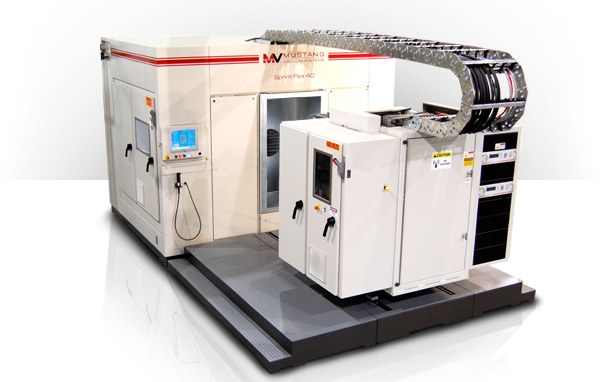

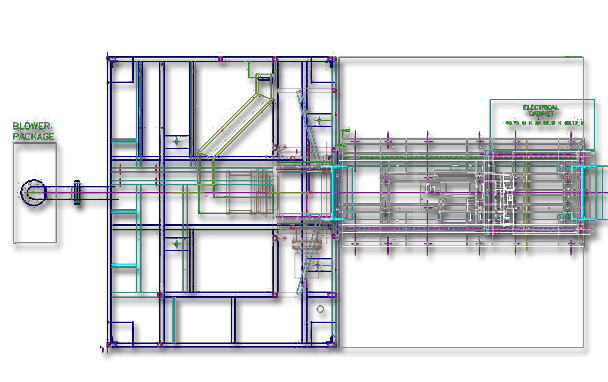

| Sprint Flex Winding film coating equipment |

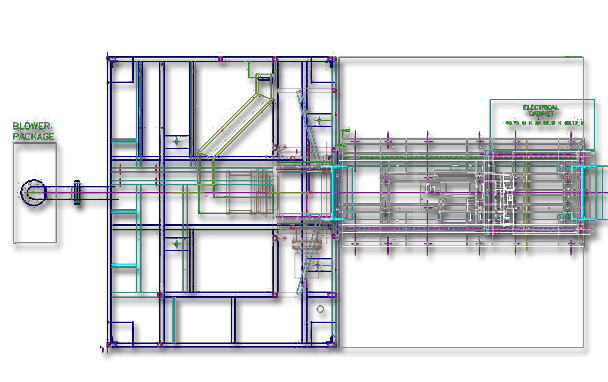

The Sprint Flex is designed for a wide range of flexible roll-to-roll deposition processes, a full range of deposition sources and multiple substrate options, with precision single-side touch material handling. Free span roll-to-roll configuration is offered with deposition on both front and back side of the substrate in a single pass to provide maximum flexibility.

Configurable with up to 4 front and 3 back side deposition sources, the Sprint Flex offers independent recipe driven control over each source, including the ability to execute multiple passes with alternating materials.

Substrate heating and pretreatment options such as ion bombardment, AC/DC/RF or plasma bombardment are available to optimize surface energy of substrates.

Mustang Solar offers applications development as well as standard processes. The SprintFlex 40 offers customers a highly robust platform for scale up of process to flexible substrates, through pilot and low volume production.

Specitications

- —Dual Direction Deposition—

- Substrates 20cm – 40cm wide

- Custom and Larger Substrate Options Available

- Film Thickness Monitoring

- Sprint Heat Rapid Annealing

- —Base Vacuum 10 x -7—

- Mechanical or Dry Roughing Pumps

- Oil Diffusion or Turbo Pumps

- Cryogenic vacuum/water pump

- —Deposition Sources—

- Planar Magnetron Sputter, Co-Evaporation, Selenium, Thermal Annealing, Custom

- —Additional Features—

- On-Board Diagnostics

- Networking Compatible

- Plasma Pre Treatment

- 1 to 7 Cathode Configurations (4 front side, 3 back side)

|

|

|

|