High Power Impulse Magnetron Sputtering (HIPIMS)

Mustang Vacuum Systems (MVS) has significant experience in the manufacture of industrial scale PVD deposition chambers comprising large area HIPIMS cathodes capable of delivering a wide range of uniquely structured hard, tribological coatings for enhanced component wear resistance and performance.

In 2005 & 2007, MVS was the first commercial organization in North America to receive and utilize power supplies (Chemfilt/ Sinex and Huettinger respectively) for industrial HIPIMS sputtering applications. Since that date significant progress and R&D has led to its routine specification in a variety of metallic and ceramic commercial coating applications.

The technique applies very high power density pulses (>1000Wcm -2 , at selectable pulse duration 50-200 µ s and frequency 100-500Hz) to a magnetron cathode to produce exceptionally high plasma densities of the order of 10 19 m -3 or greater. Such pulsed power densities enable significantly higher levels ionization (up to approx. 80%) of the metallic species liberated from the target surface than typically found in conventional magnetron sputtering processes (approx. 1-2%).

REF. Helmersson et al, Thin Solid Films, 513, 1-2, 2006, 1-24.

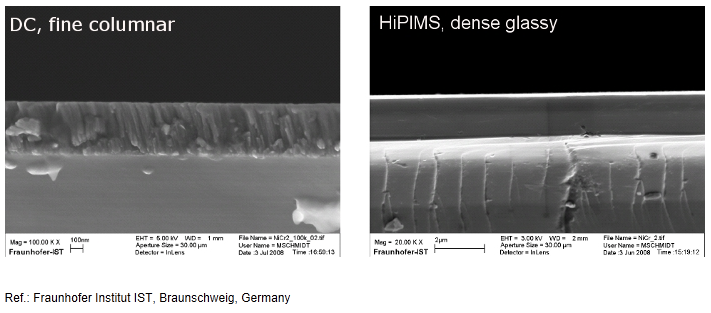

These characteristics can be used to produce significant changes in film density and preferred growth direction / orientation. HIPIMS films exhibit extremely smooth surfaces without the creation of excessive radiant heating or macro-particle incorporation typically found when using arc evaporation sources. This leads to dense, adherent films even at very low substrate temperature that are free from macro-growth defects.

|