|

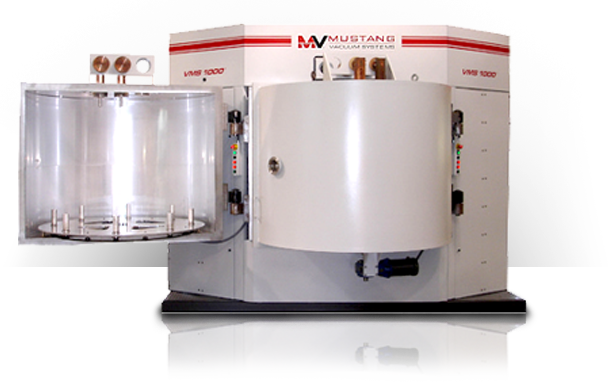

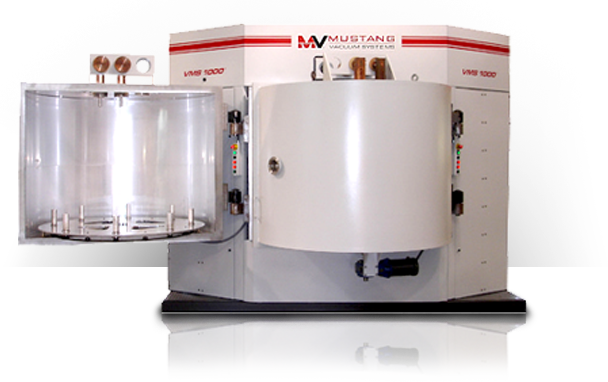

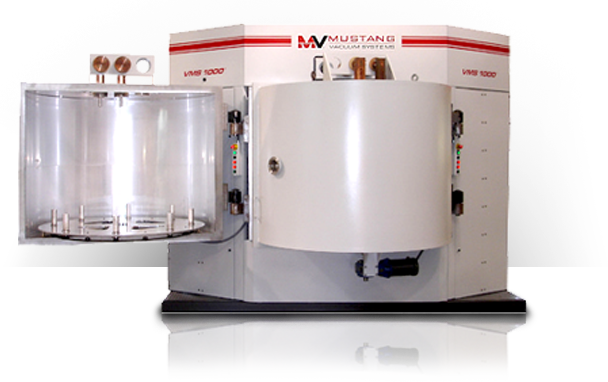

| VMS Multifunction resistance evaporation coating equipment |

The VMS 1000 and VMS 1500 are ergonomically-friendly alternatives to horizontal batch coating machines. The Mustang VMS systems offer one of the shortest evaporation cycles on the market, approximately 14 minutes, giving users a high-quality coating with Mustang's superior patented in-chamber topcoat that passes all forward lighting specifications.

Mustang manufactures the most reliable systems on the market. The VMS system is designed with ease of maintenance in mind. With over 90% uptime, customers can stay focused on meeting their production demands.

Ideal conditions, that yield the fastest cycle times, use parts directly from the plastic injection molding press or base coating line. Cycle time can be affected by substrate age, geometry and the time between maintenance intervals. Typical cycle times:

- VMS 1000: 12:00 -15:00 minutes.

- VMS 1500: 15:00 – 18:00 minutes.

Standard Aluminum Evaporation Process for high brightness reflectors and decorative finishes.

- Glow Discharge, Pre-Treatment

- Aluminum Evaporation

- Plascoat® PECVD Top Coating.

Specifications

- Tooling Capacity:

VMS 1000: Either eight (8) 430 mm (16.92 inches) or six (6) 540mm (21.25 inches)

planets with a total length of 1000mm (42.52 inches)

VMS 1500:

Either eight (8) 430 mm (16.92 inches) or six (6) 540mm (21.25 inches) planets with a

total length of 1500mm (59.05 inches)

- Quick Change Fixturing

- On-Board Diagnostics

- Networking Compatible

- Desiccant Venting Standard

- Evaporation System

- Plasma Pre Treatment

|

|

|

|